The primary functionality of a goniometer in press brake functions is in order that the workpiece is positioned at the precise preset angle right before and during the bending course of action.

It's the radius of your curved sheet metal formed When you bend sheet metal. All types get started with this vital variable. It considerably influences the dimensional precision, last energy, shape, and structural integrity.

Common calibration in the press brake’s stroke measurement system is suggested to ensure correct and regular outcomes.

Exciting news from RapidDirect! We’ve rolled out two remarkable updates to enhance your manufacturing journey.

Assure your file is in the appropriate format, and all GD&Ts are manufactured. Next, the bend line indicator is an important ingredient in communicating the look in between engineers and specialists.

Utilize a cleaning towel to dry the perimeters and bottom in the tank right up until it's cleanse. If essential, use a dough ball to pick up Filth at the welding seams or challenging-to-access regions and after that place the quilt again on.

Bottoming needs a punch with extra tonnage because it applies more force for your deformation and likewise retains the sheet for just a second once the completion of the procedure. It's suitable with V and V dies.

Torsion-Based Synchronization: The ram incorporates a complicated torsion mechanism to take care of excellent synchronization involving the two ends, making sure reliable bending final results throughout the workpiece.

Bottoming and Coining: Below, the sheet is totally pressed in to the die. This method delivers extremely exact bends but requires more power.

Are you aware of most sheet metal parts are made by very first slicing into precise dimensions, then bending into the specified condition, and assembling them? So, it performs an important function in sheet metal fabrication.

The central Handle block brings together the a few Management blocks into one, and is mainly Utilized in specialised constructions for control functions. The Management block as well as connection in between The 2 hydraulic cylinders has to be in a very symmetrical arrangement.

While confined in capacity and precision as compared to driven choices, they offer unparalleled simplicity and they are worthwhile for fast, very simple bends or prototyping get the job done.

Like a guideline, the upper the tonnage, the thicker metal that can be Find out more worked. Generally, hydraulic presses are made use of to realize pretty higher amounts of power, and pneumatic and servo electrical presses present lesser quantities of drive.

Manual bending machines are ideal for 1-off use or for your creation of areas in smaller batches, wherever a significant degree of precision isn't demanded. Having a handbook bending machine, bending accuracy and repeatability depend upon the operator's encounter.

Michael J. Fox Then & Now!

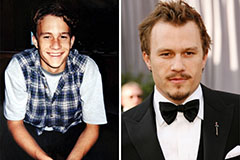

Michael J. Fox Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!